eXtra Curved skateBlade

XCBlade represents an evolutionary leap forward in skate blade technology.

A real game-changer.

RUN

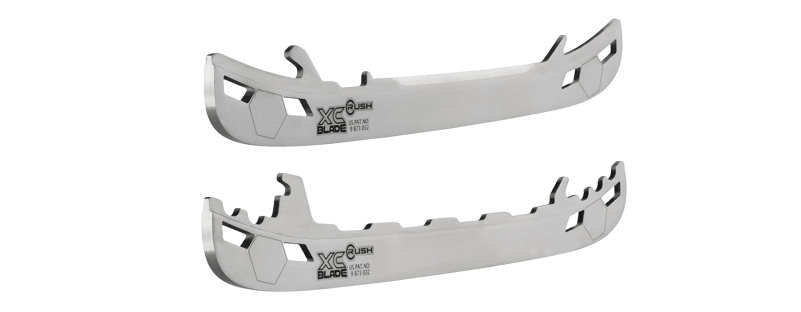

RUSH

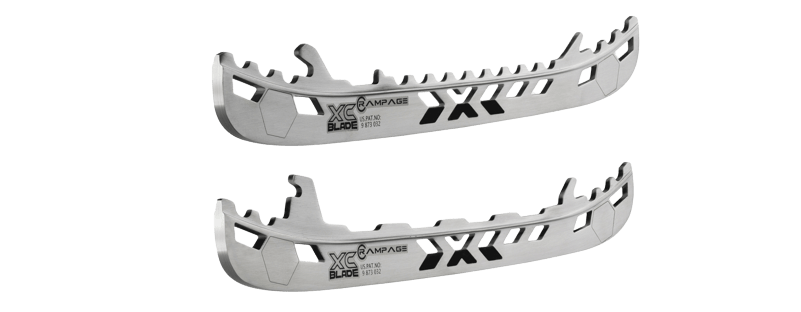

RAMPAGE

Patented design

Real innovation

Tested results

Cutting edge technology

Expanded

stability

During a crossover, XCBlades are more stable and provide more prolonged contact with ice. Depending on the model, they add up to 4 - 19% more impact.*

Increased

dynamics

XCBlades create 4 - 10% more contact with ice, giving the player more dynamic acceleration and longer pushing steps.*

High

efficiency

Due to their unique widening at the front and rear of edges, XCBlades give the player up to 3 - 11% more stable, powerful braking, and a shorter braking distance.*

Optimized

energy

The special asymmetric 3D design of the left and right edges of XCBlade allows the player to gain up to 4 - 15% more movement energy at high-speed tight turns.*

*compared to traditional blades

A whole new era in skating

In the last 100 years of modern skate development, XCBlade has been the first and only skate blade that breaks the limits of parallel edge design. With the adaption of the variable 2D edge geometry into 3D from carving skiing, it raises skating to a higher level.

3D spices up the game

XCBlade is, therefore, not a permanent but a variable-width skating blade that forms a well-defined 3D geometric shape.

Thus, unlike all currently available blades, XCBlade is NOT a parallel-edge skating blade. Still, the blade's left and right edges gradually extend from the center, parallel sections moving away from each other into the direction front and rear of the blade.

Those details matter

This change in width is different in the front and rear, more remarkable in the back region of the blade, which is responsible for tight turns and smaller in the first region, which is responsible for the longer pushes.

More ice contact, more fun

The result of this controlled expansion is that in skating situations (final phase of the pushing stage, tight and sharp turns, intense braking), where conventional blades lose their contact with the ice due to increased inclination, there, the XCBlade blades are still firmly attached to the ice surface, thanks to the widening edge design, XCBlade engages the ice with 5 - 20 % larger blade sections.

Affecting your gameplay

The parameters below represent a competitive advantage in the world of sport that makes XCBlade revolutionary.

hockey turn

During a turn the left and right skates are sliding on the ice with different radius. The special asymmetric 3D design of the left and right edges of XCBlade helps this divergent movement requirement, optimizing the energy consumption on skating. Turning is optimized with XCBlades, allowing the player to gain up to 4-15% movement energy (per match) compared to traditional blades.

This energy saving can be crucial in the late stages of a match during the endgame.

acceleration

XCBlades with their special curved 3D edge design create 4-10% more contact with ice, giving the player more dynamic acceleration and longer pushing steps.

crossover

For crossover, the blades are used with their full length, and since the XCBlades, depending on their curvature, are attached to the ice on a larger surface at the front and rear sections of the inner and outer edges, they become more stable and faster during a crossover. XCBlades provide up to 4-19% more stability depending on the model.

breaking/stop

The XCBlades, due to their widening edges are coming into contact with ice during braking both on the front and rear section on a larger surface than traditional blades, giving the player up to 3-11% more stable and powerful braking and a shorter braking distance.

straight

For straight skating, the ice-related middle area of the XCBlades is parallel, so same as any other blades, so there is no change in skating behavior except for the fact that your blades can be much shallower, allowing you higher speed.

XCBlades combine revolutionary 3D edge geometry for increased turning stability and maximum speed for straight blades.

Zero compromises only advantages.

The Story

Development engineer Miklós Makai set his mind to developing the next generation of skate blades 10 years ago.

Check out the details of his and XCBlade's remarkable story

Pro players, skill coaches, B2B partners

Our skate blades are used by hundreds of elite athletes in over 20 countries.

Adam Fantilli

Columbus Blue Jackets / NHL – 2023 1/3 draft pick

“They’ are amazing, I love how the customisation is working on the side and the width, they are great! Balance is great I feel like a lot of blade on the ice and so helps for glide everything. I’m using them, I’m loving it, so happy about it!”

Reid Schaefer

Nasville Predators / NHL – 2022 1/32 draft pick

“I’ve been using the XCBlade for the past year and overall, I’ve been able to improve my game a lot with it. I can skate faster, I’m more explosive, my whole game is faster.”

Ty Nelson

Seattle Kraken / NHL – 2022 3/68 draft pick

“They’re amazing! Since I’ve been using them, I’ve been able to get a lot tighter. Overall, I’ve gotten a lot faster, and I can feel the difference in my starts. I love them!”

János Vas

Dallas Stars / NHL – 2002 2/32 draft pick

“The XCBlade gave me more stability in turns and better balance in the straights, which proved to be key towards the end of my career. I regret that I did not experience the benefits of the XCBlade 15 years ago.”

Peter Schneider

EC Salzburg / ICEHL

“I have been using XCBlade blades since the beginning of the season. I wanted to try something new to be more stable on the ice. The XCBlade blades are great because they are wider at the end, so I get more stability and grip on rebounds and crossovers. It’s working so far.”

Mitch Zion

Clarkson Univ / NCAA

“To be honest, when I first tested this blade, I didn’t know what to expect at all. Then we started doing skill workouts: sharp bends, stick handling, etc., and the benefits of the new blade came out great.”

Robin Kovacs

Lausanne / NL

“Have used XCBlade now for 4 seasons and I am super satisfied. Have tested a few different steels over the years but have finally found the right one. I turn a lot when I play and feel like I have more steel in the ice and get a better glide with these. A fantastic steel that I highly recommend.”

Roberto Gliga

Corona Brasov / Erste Liga

“The reasons why i love and use the XCBlades are the confidence and the stability they give me going into tight corners and sharp breaks, but also the extra push getting out of them.”

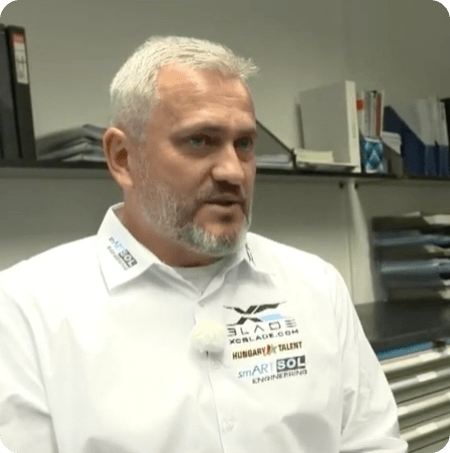

Miklós Makai

DVTK Jegesmedvék / Erste Liga

“When I use the XC, I am not only faster but also more stable in all areas. When turning, the main advantage is stability and making the tightest possible turn at speed. Moreover less energy is needed when using the blades because of the width at the end and also at the front”

Dávid Lövey

DVTK Jegesmedvék / Erste Liga

“In my opinion, XCBlade is able to give you the best stability compared to all traditional blades. When turning it helps a lot, moreover, the design is very unique.”

Bence Páterka

DVTK Jegesmedvék / Erste Liga

“I liked it a lot, it gives you an extra confidence in sharp “hockey” turns when you have to change direction suddenly. You can go into these situations with more speed because you can feel the extra area.”

Bendegúz Vadócz

Budapest Jégkorong Akadémia U21

“I’ve been using XCBlade since 3 years now. It is an amazing product. I am able to turn so much faster and deeper with it. I can only recommend it to anyone who plays hockey!”

Richard Nizielski

3 x winter olympian olympic medalist, WC medalist, skating coach

“The XC blades are a next level game-changer! The moment I stepped on the ice I could tell that these blades redefine skating excellence. The asymmetrical curve in the blades provides more stability and increased responsiveness when changing direction. The extra edge contact from the curve means I can use a flatter rocker and a shallower grind hollow. The combination, provides more glide and great acceleration capabilities. More cornering control, more acceleration and more efficiency in each stride. The era of the straight edged Ice hockey blade is over.”

Paul Ullrich

Austria (all) Skills Coach Austria U20 Asst. Coach

“Over the years I have had the pleasure of trying out many blades, but the XCBlade is the one I’m sticking with. I love how they have brought innovative technology, inspired by other sports, to hockey. It’s amazing to turn with, it’s fast and stable. I’ve got players from Germany, the Czech Republic and Austria using it.”

Dustin Korlak

Professional Skills Coach, KOR Hockey Development

“The first time I used XC blade I was extremely impressed. You feel more explosive and powerful on the ice. The control and balance from the blades is second to none. They are by far the best blades I have ever used. As a professional skills coach I demand perfection and that’s what XC Blade brings. I am thrilled to be apart of such an amazing company and represent XC blade. XC blade are ready to take the hockey world by storm”

Maxim Timoshenko

Ice hockey player, coach

“First impressions: The blades look fantastic ! The construction feel solid and really thought out. The packaging is great too with the information printed on the there. Overall, the blades look even better than I imagined and what the website photos show. The fit into the holders is great. Very precise.”

Find a partner worldwide

IMS Logistics

Ladislav Izsak

ladisims@icloud.com

Back to Basics Athletic

Liz Egeto

https://www.b2bathletics.com/

https://www.instagram.com/b2b_athletics/?hl=hu

+1 (910) 232 6116

Back2BasicsAthletics@gmail.com

inhockey.ru

Dmitrii Tuchkov

https://inhockey.ru/

https://www.instagram.com/in.hockey/

+7 (921) 650-29-25

R5 hockey

Nechai Konstantin

https://redfivehockey.com/

https://www.instagram.com/r5hockey/

+7-343-310-23-23

info@redfivehockey.com

Sport Life Care SRL

Becze Tihamér

https://www.sportlifecare.com/

https://www.instagram.com/sport_life_care/

contact@sportlifecare.com

Horvath Bence – Goldcoast Peformance Gmbh.

Horváth Bence

+41-767-97-0945

Eishockey Schlittschuhservice Hübl

Christian Hübl

https://www.instagram.com/christian.hubl/

Thirteen Sports

Thirteen Sports

www.13sports.jp

instagram.com/13sportsjapan

The Sharp Shack

The Sharp Shack

www.shorpshacklc.com

https://www.instagram.com/thesharpshack/

+1 978 413 3374

Thesharpshackllc@gmail.com

KORHOCKEY Development

Dustin Korlak

Professional Skills and Skating Coach

www.korhockey.co

https://www.instagram.com/korhockeydevelopment/

+1 204-232-4655

korhockeydevelopment@gmail.com

Share your video

Are you a top player and want to join the XCBlade squad?

Send us your review video, and we will honor your effort

„Miklós MAKAI” is a mechanical design engineer with nearly 30 years of development experience in industrial automation and precision component manufacturing.

Miklós is also the father of 3 children; all three are ice sports enthusiasts; from where came the idea for the blade improvement.

The XCBlades are manufactured in the owner's equity-financed precision plant in Székesfehérvár, Hungary - Europe, on high-precision 5-axis CNC machines at the highest technical level and quality assurance conditions. The skate blades are made in house out of swiss army knife material quality and heat treated to a hardness of 54-58HRC.

Thanks to technology and revolutionary innovations, demand is growing organically and continuously."

How can I find my XCBlade?

FAQ

XCBlade is a revolutionary 3D asymmetrical, worldwide patented hockey skate blade. Based on the benefits most similar to carving ski blades, XCBlades have widened front and back ends, thus providing more stability on turns, crossovers and brakes, while allowing more speed and power transfer.

A pair of XCBlade consists of a left and right blade of asymmetrical shapes. These blades are asymmetrical for mechanical reasons - each leg does not travel the same distance during a turn. The asymmetrical shape compensates for the negative effects of different turn lengths.

XCBlades are 23.0mm ( +-0.2mm) high, so min. 1mm higher than standard blades, providing an even longer lifespan.

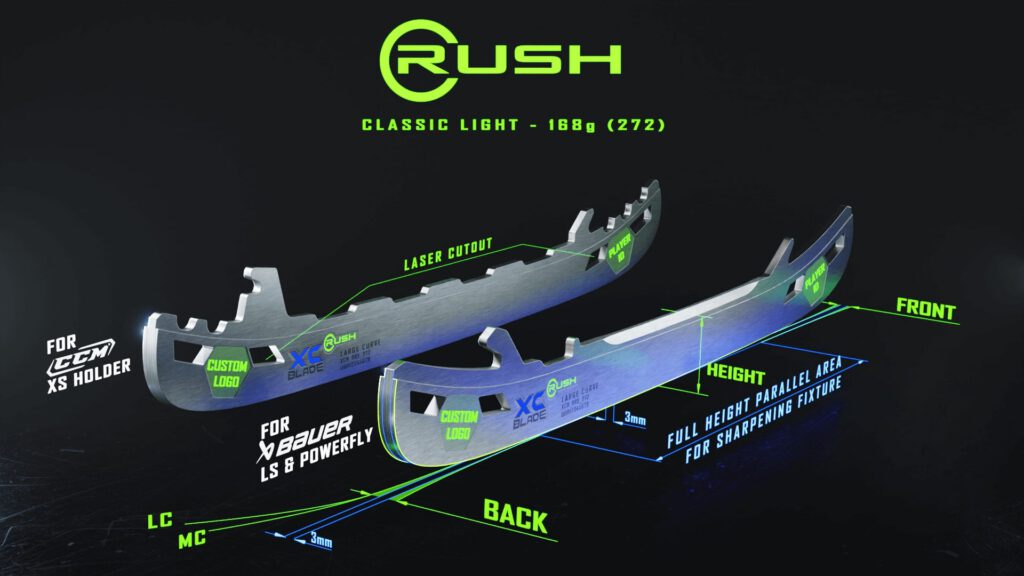

The middle section of the blades is parallel, with a thickness of 3.0mm (+- 0.05mm) just like any other blades.

XCBlades are considered light among hockey skate blades, even with the extra material added.

Run:

- XCBlade Revolution: 3D edge geometry for increased turning stability and maximum speed.

- curved back for tighter and more stable turns

- curved front for higher speed and stronger strides

- parallel middle allowing more speed

- wide range of availablity

- simple sharpening

Rush: Run +

- customizability (get your name, number and logo on your blades)

- +enlightened design (upto 9% lighter than Run models)

Rampage: Rush +

- +extra enlightened design (upto 15% lighter than Run models)

- +stiffening rib for enhanced strength

The process of creating the 3D edge of each XCBlade blade is much more complicated than the production of conventional flat blades.

This extra work means a higher price, but we offer the customer a product that provides a real competitive advantage on the ice.

The Diamond-Like Carbon coating provides the blade a longer lifespan, increases its quality, makes it more resistant to shocks and external influences, and although a single sharpening takes a little bit more time, the blade itself requires sharpening much less frequently. The blade becomes "R2R - Ready 2 Race" with the DLC.

All of XCBlades are factory profiled to SPRPS (Synthetized Penta Radius Profile Spline) profile.

This profile is better than the Prosharp Quad profile because it is synthesized from five different radiuses for the best combination of turning and gliding.

The SSP blades are unsharpened, but the DLC's of size 254 and under are sharpened to 20mm (-0.79 inches - 6/8"), and 263 and above to an ROH of 25mm (1 inch).

They get their DLC coating after sharpening, so they are - as we call them - R2R-Ready to Race right after unboxing (blades of other brands are coated without sharpening, so during the first sharpening the layer on the bottom of the blade disappears, thus losing value even before the first step on ice).

Sharpening XCBlade is as simple as it is with any other blades, you just have to pay attention to a few things. XCBlade was designed in a way that sharpening is easy and simple, neither its asymmetry nor the extra edge affects the process. XCBlade users can have a shallower hollow by up to 20-25%. This is because the extra curvature provides sufficient grip and it compensates for the bigger hollow. You may increase your speed by reducing friction. Our Sharpening Guide provides a step-by-step explanation.

Everyone can have some tips finding the suitable blade for themselves. Most of the elite, professional skaters use Large Curve blades. A good rule of thumb is: larger curve for higher center of gravity, smaller curve for lower center of gravity.

With XCBlade you may experience:

- tighter turns at higher speed

- increased dynamics at acceleration

- increased efficiency at braking

- optimized energy for skating

- increased turning stability

- MC (Medium Curve)

- Front curvature max. 0.2mm

- Rear curvature max. 1.6mm

- LC (Large Curve)

- Front curvature max. 0.4mm

- Rear curvature max. 2.2mm

- XC (eXtra Curve)

- Front curvature max. 0.6mm

- Rear curvature max. 2.8mm

SSP - Stainless Steel Polished

- Exquisite quality tool steel.

- Heat treated to 54-58 HRC hardness (material of Swiss army knifes).

DLC - Diamond-like Carbon

- Exquisite quality tool steel.

- Heat treated to 54-58 HRC hardness (material of Swiss army knifes).

What is DLC?

The Diamond-like Carbon coating provides some of the properties of diamond to surfaces of almost any material.

The primary desirable qualities are hardness, wear resistance, and slickness.

- Less friction between the blade and the ice.

- Provides longer lifespan to the blade's side.

- A single sharpening takes a little longer, but fewer sharpenings are required.

Our DLC blades get their coating and come sharpened. You only need to pop your sharpened DLC XCBlades into the holders, and they are instantly - Ready to Race.

As of our current knowledge, every single sharpening machine is fully capable to safely sharpen XCBlade. No modifications need to be made to sharpen the blades, although it requires a little more attention, because any kind of misalignment, or mis-sharpening has an increased negative impact on the blade.

Social

Share your video

hello@xcblade.com

Share a video of yourself or your friends while skating in XCBlade and share it with us.

Let us know your story and experience, and we will reshare your video on our social.